Platforms for managing energy resources in industries

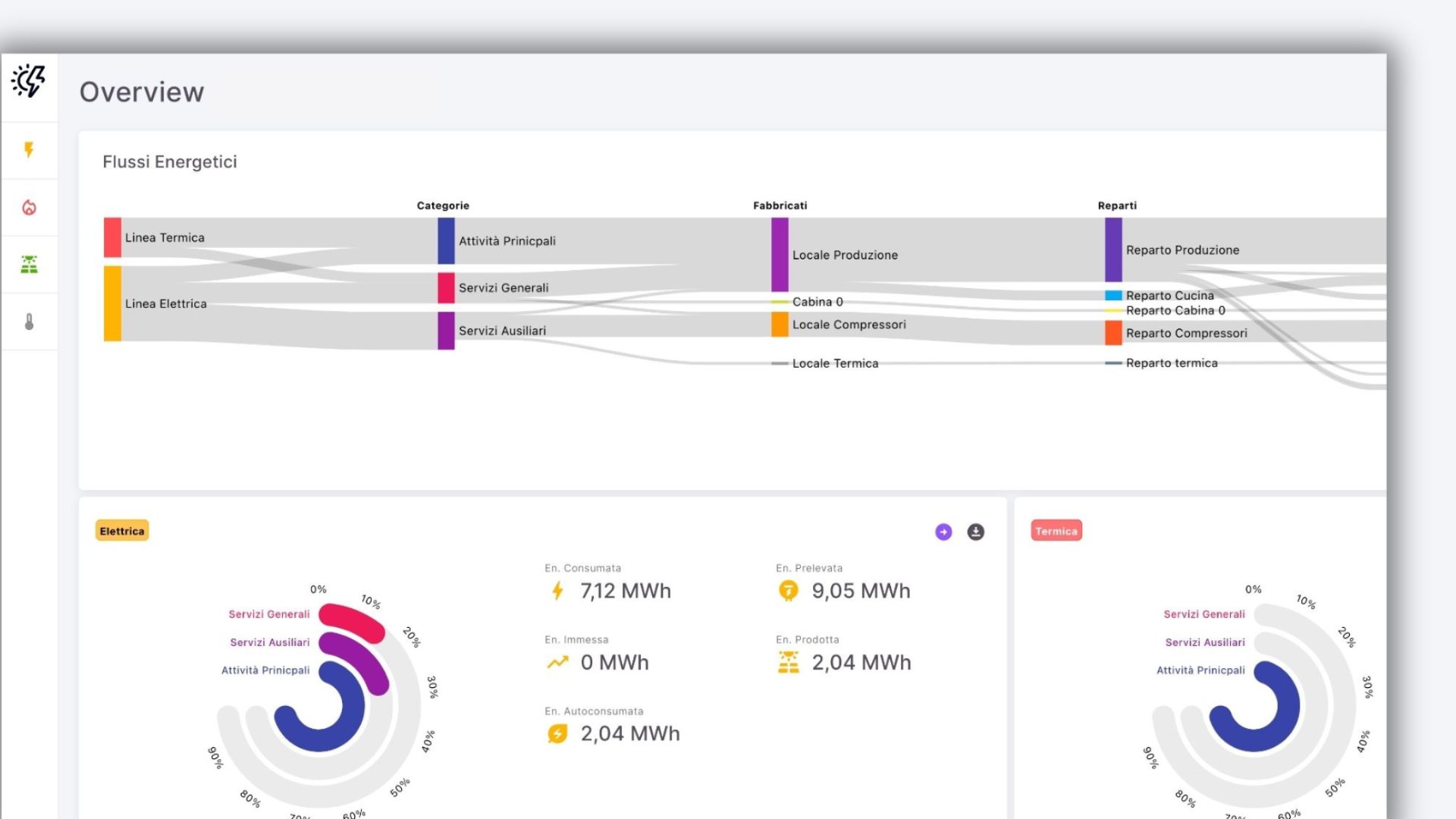

PPA and EPC models can generate significant investment returns if supported by platforms that allow the creation of a digital twin of corporate energy flows, simulating an optimization strategy, and sending automatic modulation signals to corporate energy assets.

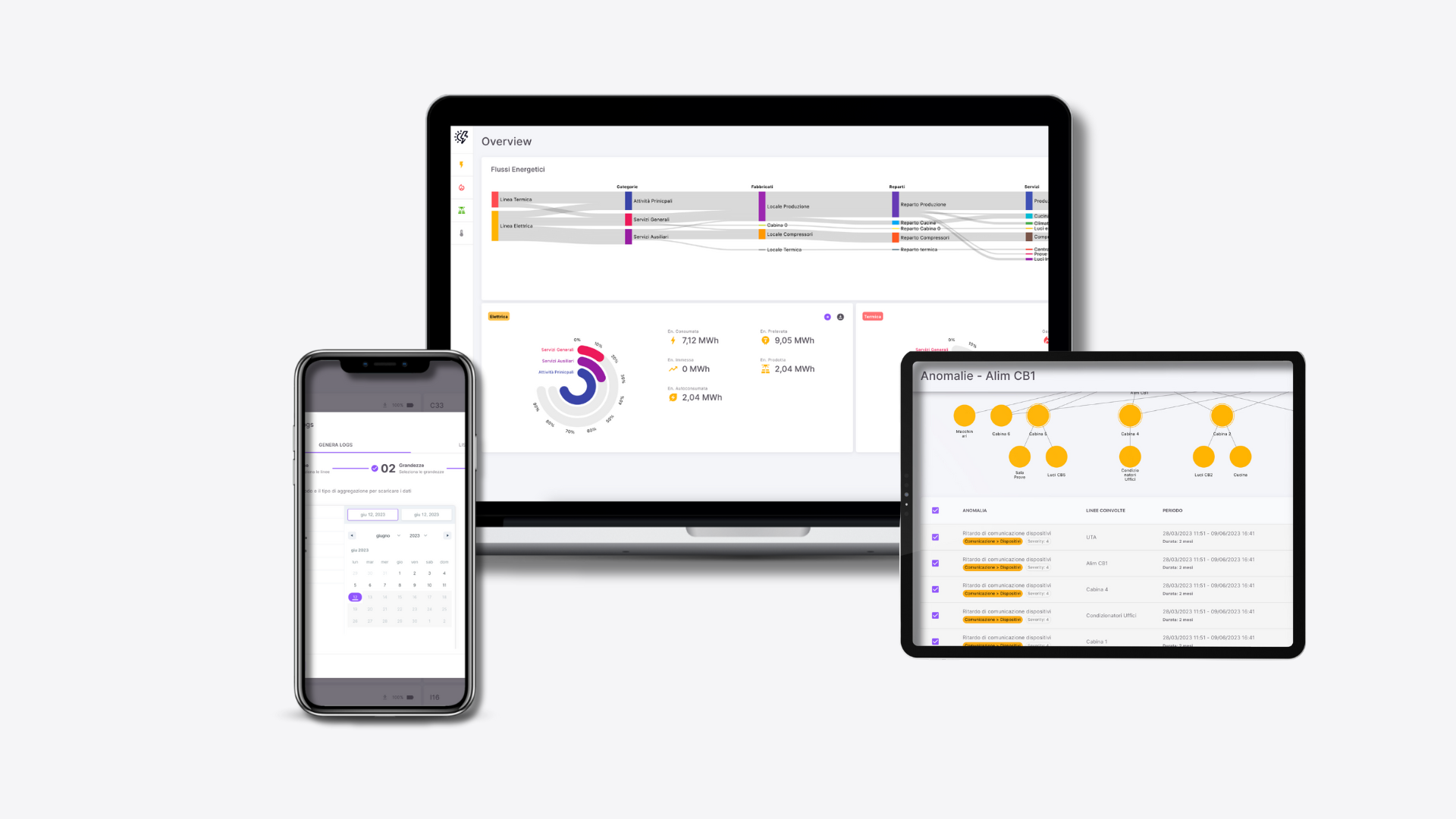

Apio, with its tools, can create customized digital platforms that accelerate the application of PPA and EPC models in the industrial sector.

How to gain an in-depth look at energy flows

Data collection and centralization

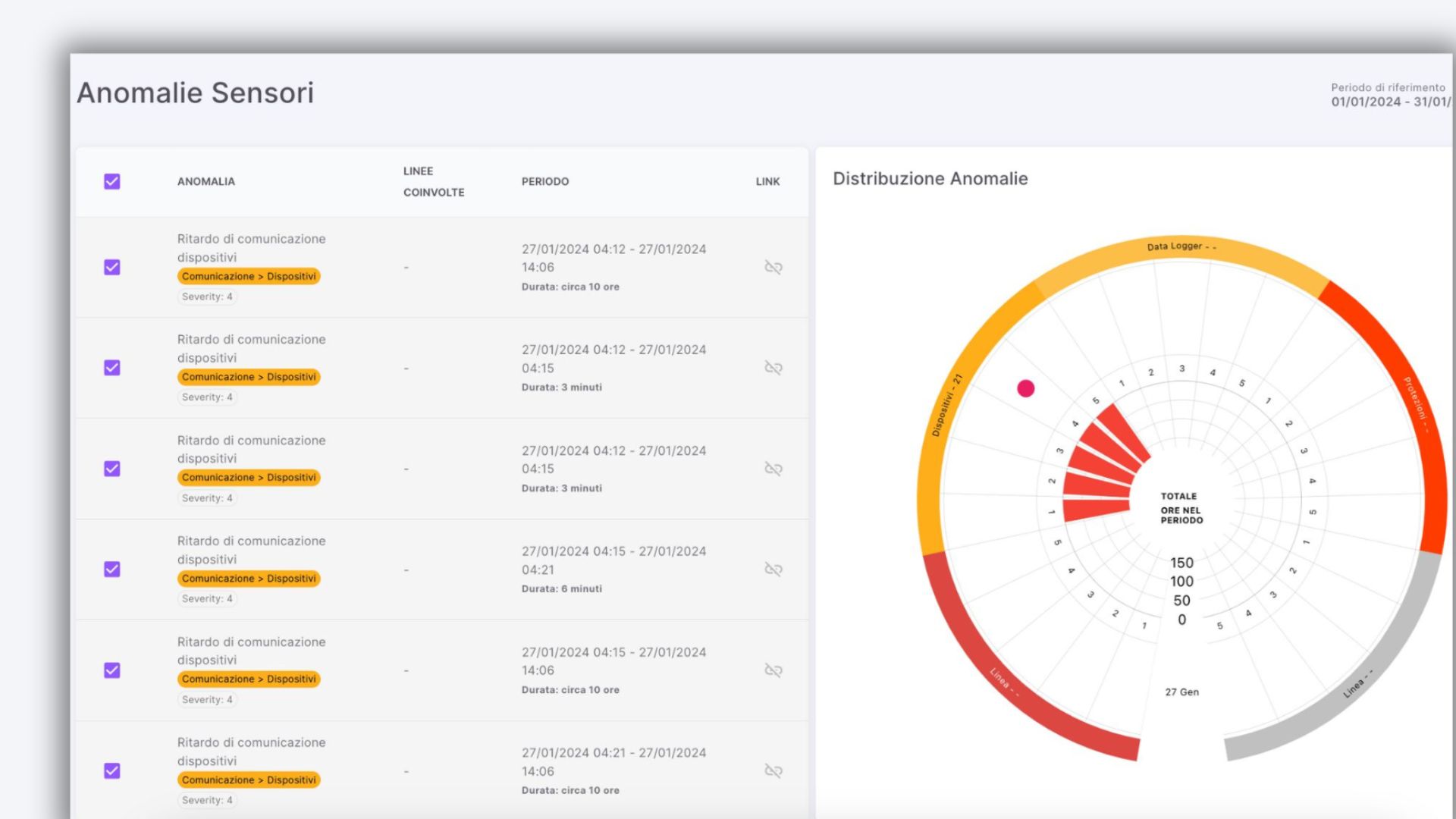

The precise detection of consumption, production, and energy efficiency data is the first step to obtaining a digital model of the company from an energy perspective. Our Apio IoT Platform allows for reliable and real-time data collection from sensors and data loggers installed to digitize corporate energy assets, such as consumption of production and testing lines, self-production plants, and energy management. Thanks to our technology, we can reduce the development times of energy digitization to a few weeks, building solutions that meet specific digitization needs, and offering an agnostic approach to the type and model of the sensor.

Continuous and secure data sharing

Managing energy within companies involves deep integration with corporate production systems. The ability to share data across different platforms becomes essential to implement energy management in synergy with corporate production lines. Our Apio Data Platform enables data sharing among the high number of systems used within companies. BMS, EMS, MES, ERP, and other energy management systems can interact with each other with speed, security, and continuity, ensuring the execution of EPC and PPA models that require a high level of managerial complexity.

Converting data into strategic information

Data mining and machine learning are techniques that allow predicting future behavior from a reliable cluster of historical data. With Apio Forecasting Platform, we have made the application of the most popular data mining models immediate, robust, and scalable. In this way, we manage to extract a measurable scheduling plan of energy resources that maximizes the synergistic use of consumption, self-production, and energy management, offering a high degree of guarantee of contractual constraints and respect for the company and its counterpart.

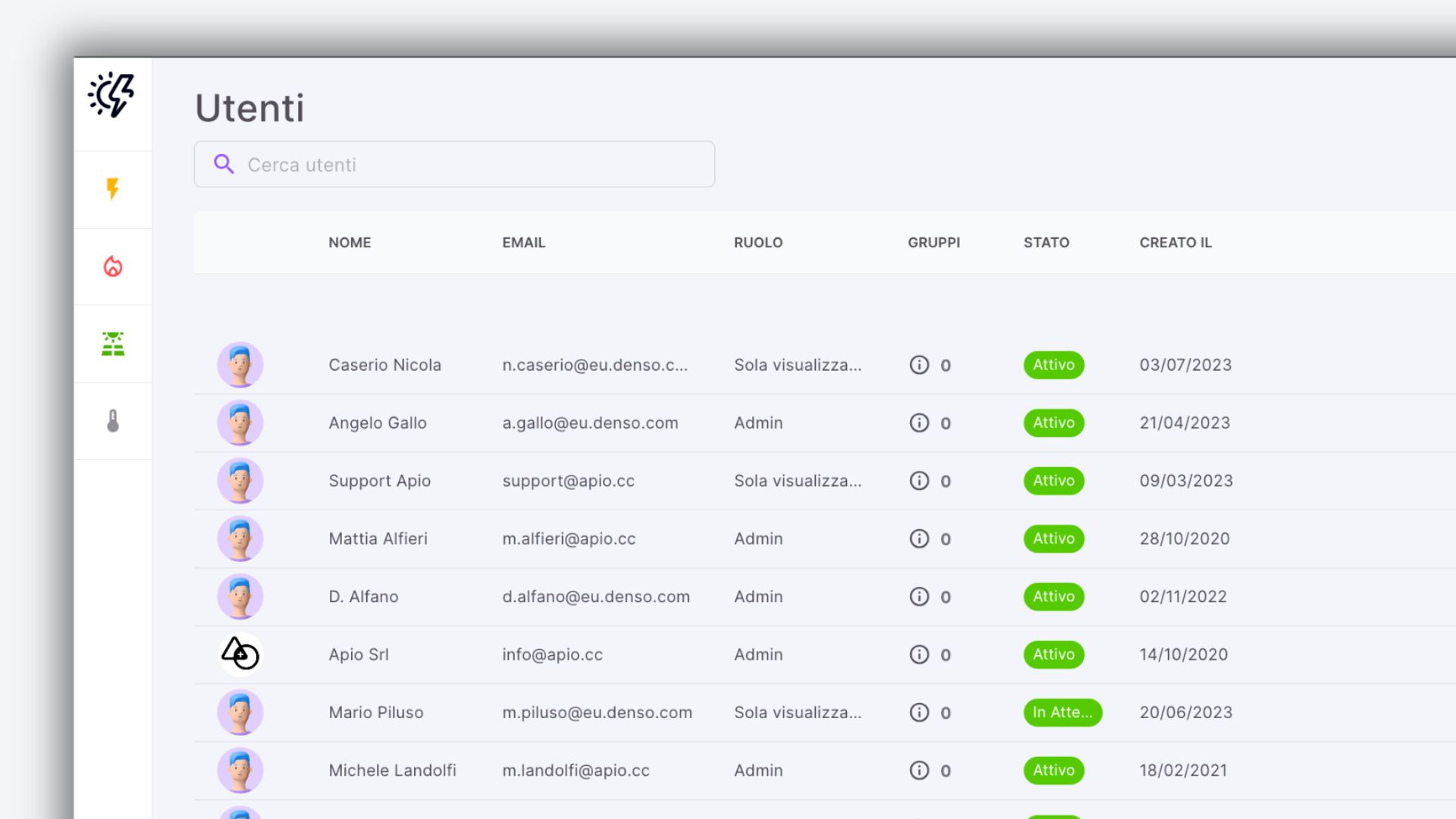

Customized management for users and groups

Managing a vast portfolio of EPCs and PPAs requires the interaction of various professional figures. Our platforms, built with a strongly user-friendly approach, ensure immediate and targeted data access. With Apio Identity Provider, we can quickly implement detailed and customized management of users and groups, allowing the creation and sharing of access privileges across different platforms while maintaining the highest standards of security and privacy.

Apio's figures in managing industrial energy efficiency

+50

daily monitored buildings

+100 GWh

daily energy managed

+20%

saving by predictive mantainance

Use Cases

DENSO

To achieve a level of in-depth analysis capable of calculating the economic impact of the energy consumed per unit price produced, engineers at Denso, an international company of the Toyota Group that manufactures integrated systems and automotive components, have requested a solution that ensures continuity with the company's systems. Precise monitoring is capable of providing a detailed overview of energy carriers in the San Salvo (CH) plants.